3 Products

Next Working Day Delivery*

Order by 5pm

Free Shipping

On all orders over £150

Rated Excellent by our Customers

4.7* Reviews

No Compromise on Quality

Exceptional products, every single time

Expert Service & Advice

Contact us by phone, email or chat

Collection: Plant Nappy®

Plant Nappy® and PlantMat®

Lapwing are specialist stockists of the Plant Nappy® and PlantMat® family of spill containment products for the construction industry. Manufactured in the UK by Manvers Engineering, the innovative patented Plant Nappy® & PlantMat® products solve one of the construction industries persistent pollution risk problems: how to contain oil & fuel spills in a hostile environment, in often harsh terrain and in all weathers?

What is The Plant Nappy® made from?

Manufactured from abrasion resistant, UV stable and fire-retardant materials, the Plant Nappy® is a flexible, portable drip tray with PVC coated foam filled side walls that are crush resistant – returning to shape after being compressed – unlike plastic trays which break and metal trays that stay deformed. The Plant Nappy® works by allowing water to drain away whilst retaining hydrocarbons within the Nappy – this prevents the risk of oil ‘float off’ inherent in traditional drip trays in wet conditions.

What does The Plant Nappy® range offer?

The Plant Nappy® range includes replaceable liners that complement the Nappy by increasing the absorption capacity and prolonging the life of the Plant Nappy®. The liner snugly fits the Plant Nappy and is easy to remove for cleaning or replacing.

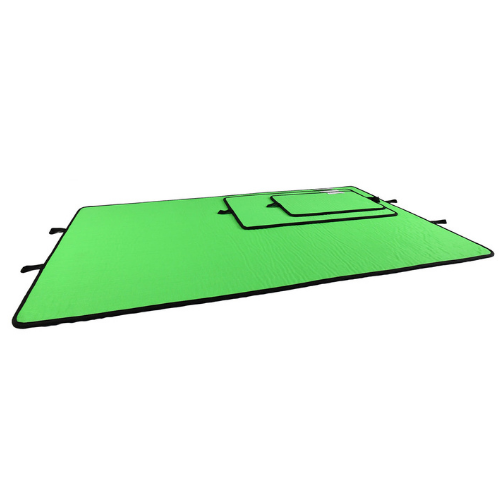

The Plant Mat® is the latest addition to the spill control range and is designed to augment the Plant Nappy® and can used alone or within a Plant Nappy®.

How does The PlantMat® work?

This innovative product uses the Soliditex® technology which is a patent applied for unique mix of polymers that capture & solidify hydrocarbons whilst unaffected by water, which simply drains away. The solidified spill material makes subsequent handling and disposal much easier.

Manufactured from durable materials, the PlantMat® is equal for deployment in the harshest conditions. Use in conjunction with the Plant Nappy® for a comprehensive answer to your small plant siting and refuelling pollution risks – providing low cost, flexible and effective spill containment.

How can Lapwing help you?

Lapwing stock the Plant Nappy® and the PlantMat® in the most popular sizes – from Small – 500 x 685mm, to Medium – 685 x 1000mm and Large at 1370 x 2000mm providing a nappy suitable for a large variety of plant & equipment.

Plant Nappy® Technical Specification:

- PVC Coated Mesh material with high tensile strength

- Oil & Chemical resistant

- UV resistant

- Temperature resistant – operating range -20 to 107ºC. (melt Point 157ºC)

- Reticulated foam with auto memory shape

- Crush resistant.

- Polypropylene fibre filler, which is nontoxic, non-hazardous.

- High oil to fabric weight ratio of absorption

Plant Nappy® Disposal

The Plant Nappy is designed to be reused, time and again. It can be wrung out into a suitable container and pressure washed in a suitable controlled environment – simply wash, allow to dry and re-use. However, it will eventually need disposal. All waste transfers are subject to The Waste (England & Wales) Regulations 2011. The first consideration for disposal is: is it contaminated? If yes it will fall under waste code 15 02 02 – absorbents, filter materials (including oil filters not otherwise specified), wiping cloths, protective clothing contaminated by dangerous substances. If used in construction, it will fall under 17 09 04 – mixed construction & demolition wastes.

If uncontaminated it can be disposed under 20 03 01 mixed municipal waste.