31 Products

Types of Concrete Tools Available

Lapwing has a wide range of different concrete finishing tools. We stock an array of hand floats, placers, screed bars, tamps, mould oils and concrete curing agents, along with Magnesium Bul Floats and Fresno Broom Floats, ideal for creating a high-quality surface finish. Large stocks of the Big Blue easy float are held both as complete kits and as replacement components. Lapwing has all the concreting tools you could ever need all at affordable prices.

Concreting Tools for Mixing and Levelling

-

Mixers

Mixers are essential pieces of concrete tooling for construction professionals, facilitating the thorough blending of cement, aggregates and water to create a consistent and workable mixture. They save time and effort for users by automating the mixing process, ensuring uniformity and enhancing the efficiency of construction projects.

-

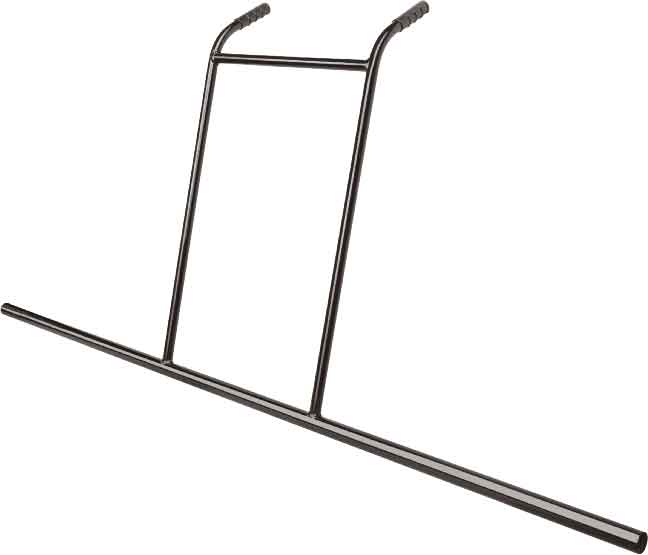

Construction Floats

Construction floats are concrete finishing tools used to level and smooth concrete surfaces. They minimise the need for heavy manual labour by providing a smooth and even finish. Lapwing’s range of construction floats allows users to accomplish professional outcomes, shorten project durations and improve the visual aesthetic of concrete structures. Many of the Big Blue range of floats feature adjustable handles and extensions as well as being stocked in various sizes.

-

Concrete Rakes

We have an extensive range of concrete rakes, all designed for spreading and levelling freshly poured concrete. This range of professional concreting tooling helps achieve even distribution and eliminate air pockets, leading to a smoother and more durable finish. A concrete rake from Lapwing enhances efficiency, minimises concrete waste and promotes a higher-quality outcome for construction projects, making them invaluable to users in the industry.

-

Concrete Groovers

Purchase our concrete groovers; perfect for creating grooves or patterns in concrete surfaces, providing unique aesthetics and controlling cracking. These concreting tools are widely used in various industries, including landscaping and road construction, allowing users to add decorative elements to surfaces, improve traction on walkways and help to enhance the durability of concrete in different applications.

Why Proper Concrete Tooling Matters for Contractors

Using the proper concreting tooling that’s not only fit for purpose but also constructed using high quality materials is crucial. Sub-par tooling can lead to poor work, and mistakes in concreting work, particularly in surface finishing, can be difficult to correct.

Our range of premium, cost-effective concreting tools is designed to help you work at your best and see results you can be proud of. Better yet, when you check out before 5 pm today, you can enjoy next working day delivery and free shipping when you spend £150 or more.

Get in Touch for Expert Advice on Choosing the Best Concrete Tooling for Your Project

Not sure which tooling is best for your next project? Not to worry. Our expert team is always on hand to offer advice and support and help you find the perfect concrete tools.

Just give us a call now on 01386 551 090 or fill out our contact form.

FAQs

What tools do I need for concrete work?

For concrete work, you may require various concrete tools such as a mixer for mixing, forms for shaping, trowels and floats for finishing, concrete saws for cutting and measurement instruments for detailed laying accuracy. Other tools may include concrete vibrators for compaction, a levelling screed and wheelbarrows and buckets which are a part of Lapwing’s construction site supplies. With the help of these concreting tools, you can mix, pour, shape and finish concrete with accuracy and excellence.

What tools do concrete workers use?

To perform their jobs effectively, concrete workers will use a range of tools. Mixers, trowels, forms, floats, edgers, bull floats, concrete saws, screeds, concrete vibrators, measuring devices, transport tools, such as wheelbarrows and concrete buckets. Each tool has a distinct function that enables concrete workers to accomplish their intended outcomes precisely and quickly. Lapwing supplies a wide range of the best concrete tools for contractors - explore our range.

How to remove dried concrete from tools?

Although removing dried concrete from tools can be difficult, doing so is necessary to keep them functional. Start by scrubbing away any extra concrete with a wire brush. If the concrete is hard to remove, soak the tools in water until it becomes pliable and then use a chisel or brush to scrape it off. Metal tools can be kept from accumulating lots of dried concrete by routinely cleaning, oiling or greasing them. Maintaining your concrete tooling properly can guarantee it remains functional for years to come.

Where to buy concrete tools?

You can buy the best concreting tooling for contractors right here from Lapwing! We have a host of concreting tools for sale made from the highest quality materials and able to handle a wide variety of concreting projects. We have affordable concrete finishing tools for decorative needs, as well as finishing trowels, concrete placers, screed bars, concrete rakes, mould oils and much more. For more information, contact us today.

What are the best concrete finishing tools for contractors?

The best concreting tooling will vary based on the task at hand, but some of the best tools to have on hand include:

- Square-edge shovels

- Screed boards and straight edges

- Floats

- Trowelling

- Edging tools

At Lapwing, you can find the perfect selection of concrete tools for almost any task. If you’re unsure which tools you need, just call our friendly team now on 01386 551090.

How do you maintain concrete tools after usage?

There are a few key tips to help keep your concrete tools in top condition:

- Remove any debris – after each use, make sure to remove any debris from your concreting tools, otherwise it can interfere with your next task.

- Regular lubrication – for any mechanical tools, implement lubrication schedules to ensure moving parts don’t seize or rust.

- Check blades – ensure you regularly inspect any cutting or abrasive surfaces for signs of dullness or wear and sharpen or replace as needed.

- Proper storage – finally, properly storing your tools can keep them at their best for longer, keeping them away from damp or unnecessary damage.